|

|

|

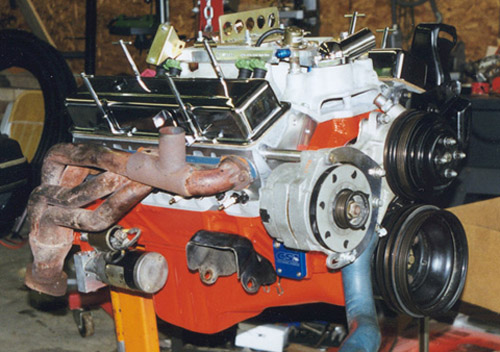

Pictures of the 385 with AFR cylinder heads and the Pro Flo Injection.

My son took this one. Notice the altitude :) The air cleaner is an

Edelbrock Pro Flo unit that I use at the track. It gets dirty too quickly

for normal, everyday use. This picture also shows the AC system installed,

but on the next page, it is not yet installed. The engine looks a whole lot

better without it, but the driver tends to complain in the summer time :)

Add some crusty old parts and were almost there. A friend of mine

made the alternator mount out of some aerospace aluminum. This stuff

is strong! It locates the alternator 180 degrees down from the normal

position. The Victor Jr. manifold doesn't have the boss for the top bracket

for the alternator, so something had to be done. He was already using this

setup on his 1970 Monte, so he made one up for me. After looking at the TES

system and its rustiness, I took a wire brush and shined them up a bit before

we put the engine back in the car. They are 6 years old now, so I don't mind a

little corrosion. I am amazed at how well they have held up over the years.

I thinkthey might be holding this engine back some now, so bigger

headers are on the horizon.

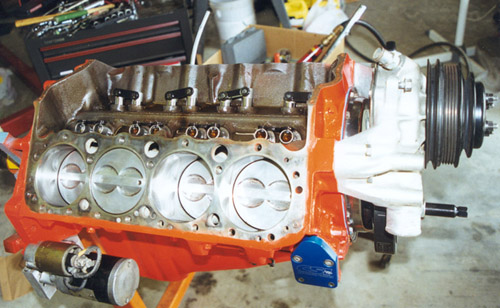

Picture of the previous 355 rebuild

View of roller lifters and 140,000 mile bores. I decided not to have

the cylinder re-bored. They looked great. I did de-carbon the tops of the

pistons though. The main and rod bearings were replaced, but after looking

at them, people asked me why-they looked barely worn! After the engine was

back in the car, it is getting about 5000 miles per quart of oil over the last 9

months of driving. Apparently the rings still have a darn good seal!